Print and Apply Labelers

Print and Apply Corner Wrap Labeling System

Features

- 5/8″ thick anodized aluminum side plate construction

- Straight label web path

- RFID ready

- Microprocessor controls with 50 programmable product presets

- Modular chassis for ease of debug and maintenance

- Integrated printer fault monitoring with stack lamp

- Optional General Purpose IO interface

- Quick disconnect sensors and pneumatics

- Integrated photoelectric product detect sensor

- Machined U-Mount style mounting yoke

Quadrel’s Corner Wrap printer applicator is a rugged print and apply system designed for the most demanding variable information labeling requirements for high-speed leading panel to side applications. This applicator prints and applies labels to various products, shipping cases and pallets with products rates up to 30 products per minute and comes standard with low label detection, end-of-web detection and printer faults with two light stack lamp.

Q34 Printer Application

Features

- Allen Bradley© Micro800 Series PLC control

- Password protection

- Onboard Diagnostics

- Product counter, label counter, and product per minute display

- Stainless steel electric chassis and 5/8” aluminum side plate construction

- Innovative machined mounting yoke for positive applicator positioning

- Clear polycarbonate back cover permits instant inspection of all internal components

- Tamp cylinder assembly pivots away from printer for ease of threading and maintenance

- All sensors feature quick disconnect fittings for ease of service

- All pneumatics also feature color coded tubing with quick connect fittings

- Plasma coated air assist tube eliminates adhesive buildup

- Dual action rewind permits printer back feed at the beginning OR the end of print sequence

Quadrel’s new rugged and compact Q34 is the most innovative print & apply labeling system available today. The Q34 contains several unique design features not found on other printer applicators, yet the Q34 is heavy duty enough for the most demanding 24/7 applications and the harshest environments. The Q34 is available with several application modules including air tamp, air blow, tamp blow, wipe on and pneumatic swing arms for side, top leading edge, adjacent side or corner wrap applications. The Q34 may also be built into a heavy duty pallet labeling system. The Q34 is available with Zebra, Sato or Datamax print engines.

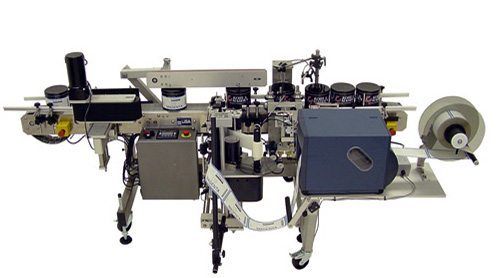

Q34 Adjacent Side Labeling System

Features

- Allen Bradley© Micro820 PLC control

- Allen Bradley© Panelview 820 series 4″ color touchscreen HMI

- Password protection

- Onboard Diagnostics

- Product counter, label counter, and product per minute display

- Stainless steel electric chassis and 5/8” aluminum side plate construction

- Innovative machined mounting yoke for positive applicator positioning

- Clear polycarbonate back cover permits instant inspection of all internal components

- Tamp cylinder assembly pivots away from printer for ease of threading and maintenance

- All sensors feature quick disconnect fittings for ease of service

- All pneumatics also feature color coded tubing with quick connect fittings

- Plasma coated air assist tube eliminates adhesive buildup

- Dual action rewind permits printer back feed at the beginning OR the end of print sequence

- Lightweight swing arm for high speed applications

Quadrel’s new rugged and compact Q34 is the most innovative print & apply labeling system available today. The Q34 contains several unique design features not found on other printer applicators, yet the Q34 is heavy duty enough for the most demanding 24/7 applications and the harshest environments. This system applies two separate labels to a carton or box. The first label is printed, and applied to the leading edge of the box or carton. A second label is printed and applied to the center of the adjacent side.

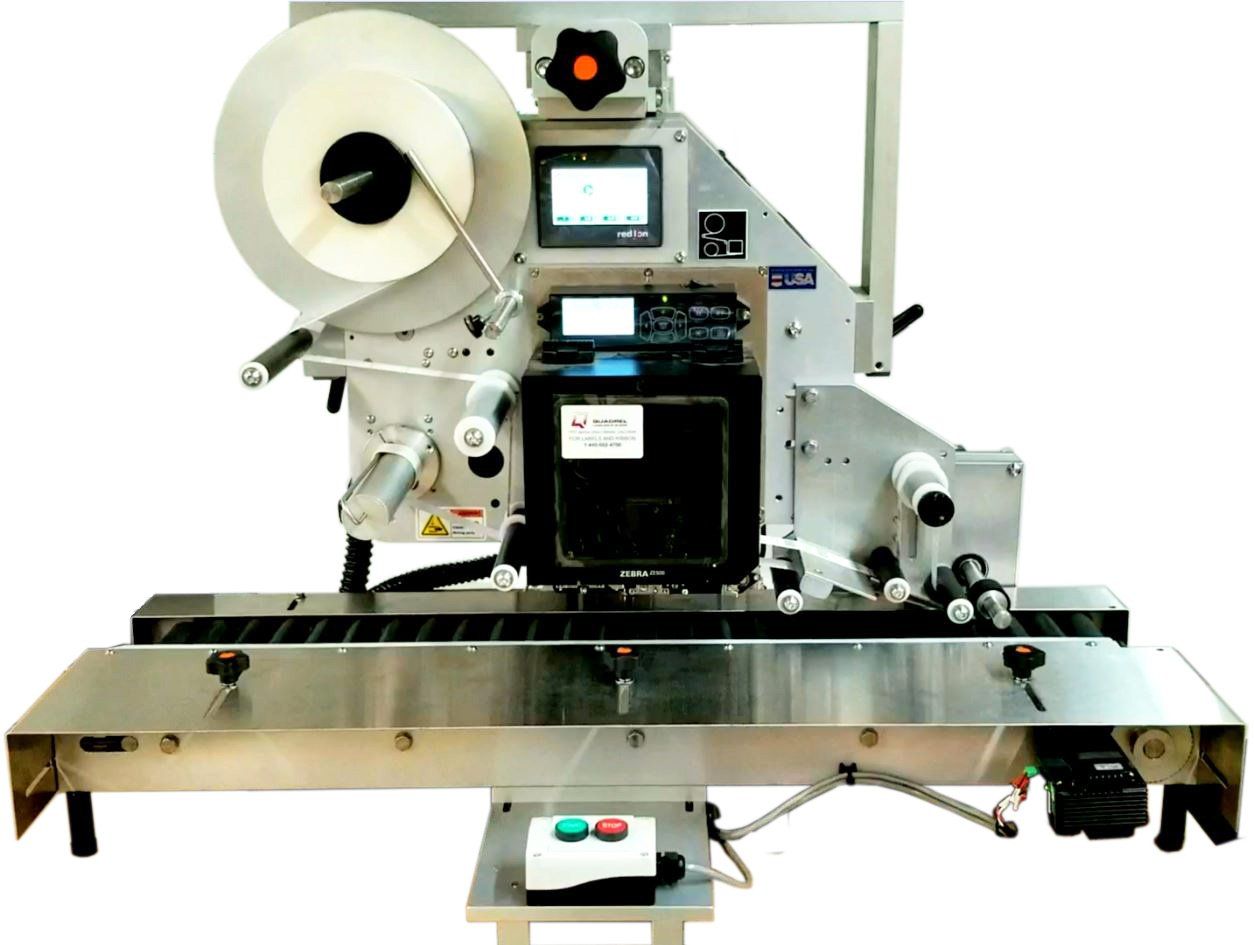

Q60 Loose Loop Printer Application

Features

- Dimensions: 33.98”L x 25.05”W x 23.23”H

Electrical: 115 VAC @ 15 amps; overload protection built in; 220 VAC @ 7 amps - Environmental: 41-1040 F (5-400 C); humidity 15-85% RH non-condensing

- Printing Methods: Thermal-Transfer or Direct-thermal

- Print Resolution: 203, 300, 600 dpi

- Print Width: 4: 4.1” (104mm) or 7: 7.1″ (108mm)

- Print Speed: Up to 12.0” per second (305mm)

- Label Roll Size: Maximum diameter 16.00” O.D. (406mm)

- Labeling Speed: Contingent upon print speed and label length up to 250ppm

- Label Dispense: Accurate to ±0.03” (.76mm) when labels are produced to specifications

The concept of Loose Loop printing separates the tasks of Printing and then Applying commonly found in traditional Printer Applicators; with a Loose Loop configured printer, the label applications are no longer “One to One.” Printing is done in a continuous manner based on demand from the label applicator. As the loop in the vacuum box diminishes, the printer prints more labels to fill the box. The applicator continuously runs like a traditional Merge Style labeling head while the printer continuously supplies the web path with printed labels. The integrated design of the Q60 Loose Loop allows OEM style printers to print at a slow comfortable speed to maintain excellent print quality while the labels are applied at high cycle rates. With the compact, single side-plate, design, the loop of printed labels is kept to a minimum unlike remote printers with web turn bars.

Orienting with Thermal Transfer Printer Labeling System

Features

- Available with full color Thermal Transfer label printing

- Wide label printing capabilities

- Print right on the production floor

- Small compact design

- Variable speed with encoder compensation

This labeling system applies labels to a specific point on a cylindrical product. The 3-roller indexing module captures the product and rotates it to a reference point. Once the position is known, the label is dispensed. A wrap station completes the label wipe down around the product.

Print and Apply Front/Back Labeling System

Features

- True “Next-Out” label application

- Variable data on both sides of the container

- Precise bottle handling

- Integrated frame with compact foot print

- Variable speed conveyor

- Available with Stainless Steel or Carbon Steel frames

This Front/Back Labeling System features two opposing printer applicators. Product handling features a ten foot conveyor, a top hold down assembly for product control and two bar code scanners with pneumatic cylinders for ejection of bad read bar codes.

Print and Apply Pail Labeling System

This print and apply system with a leading panel corner wrap assembly and pneumatic roller impresser. The print and apply labeling system predispenses a label to the leading panel module, the label is applied to the leading panel and the pneumatic roller impresser completes the label wipe down onto the side of the product. To label the pails, the print and apply applicator prints and applies a label to the side of the pail. The wrap station completes the label wipe down as the product spins. Additional features include a custom width and length stainless steel conveyor, guarding for the wrap station and custom product wheels.

Print and Apply Wraparound Labeling System

Features

- Integrated Frame with compact foot-print

- Variable Speed Conveyor

- Choice of “Wipe-On” or “Tamp” label application techniques

- Variable speed bottle wraparound belt

- Casters and leveling pads

- “Wheel-up” convenience

Labels are printed, and as the product contacts the label, it is applied to the leading panel. The impressers complete the label wipe down onto the side of the container. The wrap station completes the label wipe down around the cylindrical containers.

Q34 Pallet Labeling System

Features

- Robust stainless steel and anodized aluminum construction

- Microprocessor controls with intuitive password protected menus

- 50 programmable product profile presets

- Quick disconnect electronics with integrated optical sensors

- Integrated U-Mount style mounting yoke

- 24/7 reliability

- “Straight” web path compatible with most RFID and Linerless labels

Quadrel’s pallet labeling system features include an all stainless steel frame, premium high cycle rate air cylinders, rugged 5/8” side plate construction and PLC control with touchscreen. The over-sized H-Base stand provides superior stability and includes a spring detent breakaway feature allowing the system to rotate freely out of harm’s way in the event that it is struck by an out of position pallet.

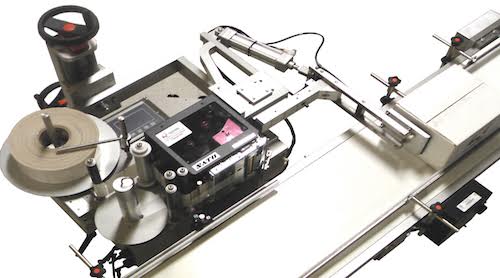

Q34 Vial Labeler

Features

- This is a custom table top horizontal labeling system for syringes.

- It is also capable of labeling other pharmaceutical products such as vials and ampules.

- This is a hand loaded system features on-demand thermal transfer printing allowing its use with blank labels.

- This system was designed specifically for use in compounding, testing or R & D facilities.

- Speed capability is limited due to hand loading. Rates are usually 20 to 30 ppm.