Bottle Unscramblers

Omni Line

Features:

- Moderate to High speed applications

- Heavy-duty design with Stainless Steel Construction

- Versatility in running many bottle formats and sizes on same machine

- Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, trigger sprays and other odd shaped bottles

- "Tool-less" changeover is fast - usually in less than 10 minutes

- Floor level access to all machine parts

- Five Standard model sizes available: M350, M400, M500, M600 & M800

- Two High Speed model sizes available: M800HS & M1000HS

The established line of Pace bottle handling equipment has been designated Omni-line. These machines have earned a world-wide reputation for reliability, versatility and performance. Omni-line machines are universally-suited for production in all packaging industries, most notably in: beverage, bottled water, food, personal and household products, motor oil and bottle decorating.

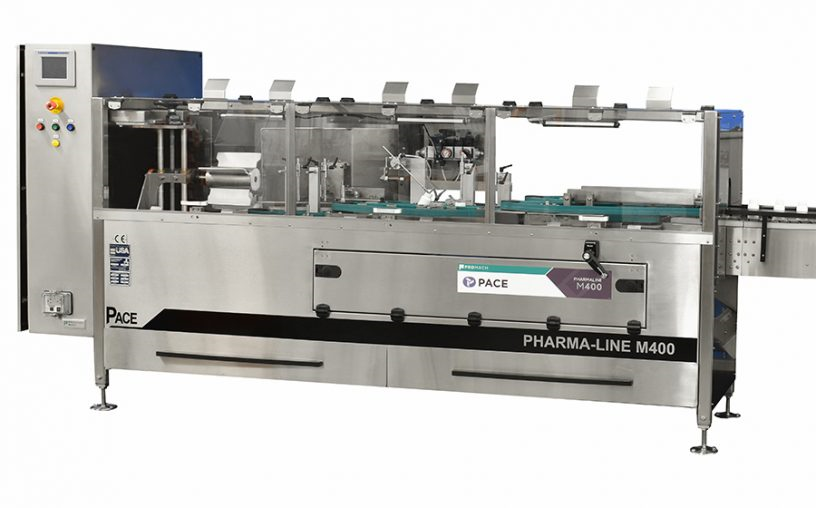

Pharma Line

Features

- Low to Moderate speed applications

- Pharmaceutical GMP design with Stainless Steel Construction

- Suited for tablet and small bottle applications

- Capable of handling rounds, cylinders, jars, ovals, squares and rectangles

- "Tool-less" changeover is fast - usually in less than 10 minutes

- Floor level access to all machine parts

- Integrated ionized air rinse station and "No Change-Parts" options available

Building upon our vast knowledge and experience in unscrambling technologies, Pace Packaging designed a hybrid unscrambler that was based upon our popular Omni-line series, but incorporated the specific requirements of the Pharmaceutical industry - Pharma-line was born. Pharma-line machines, with their integrated inline ionized air rinse and concurrent vacuum, are well suited for production in all pharmaceutical, nutraceutical and vitamin industries and are specially designed to handle all tablet and liquid containers: rounds, squares, rectangles, ovals and jars.

Bottle Orientators

BAO 5000

Features:

- Orientor can work as a stand-alone unit or in conjunction with an Omni-line unscrambler

- Heavy-duty design with Stainless Steel Construction

- Able to run many bottle formats and sizes on same machine

- Capable of handling symmetrical and non-symmetrical bottles

- Synchronous single drive control for top and bottom conveyors

- "Tool-less" changeover is fast

- Floor level access to all machine parts

Our Omni-line series of Automatic Plastic Bottle Orientors have earned a worldwide reputation for reliability, versatility and performance. Omni-line orientors can handle off-center neck bottles, F-style bottles, trigger sprays, bottles with external handles, bottles with interior handles, silk screened bottles, inmold label bottles and other odd shaped bottles. Applications include bottles used in the motor oil, laundry detergents, juice jugs, food, personal care and household cleaning industries.

BAO OTC

Features:

- Moderate speed applications

- Heavy-duty design with Stainless Steel Construction

- Utilizes customer conveyor

- No side transfer

- "Tool-less" changeover is fast

- Floor level access to all machine parts

The BAO OTC (Over The Conveyor) is the perfect solution for 180o orientation. This orientator is specially designed to utilize the customer's conveyor and no side transfer.